Pneumatic Systems Compressed Air Audit

Known as the fourth utility in manufacturing plants, Compressed Air stands out as a significant energy consumer, quite possibly ranking as the largest. Despite its widespread application across various manufacturing sectors, Compressed Air remains one of the most misunderstood utilities and a key target for cost reductions. Fortunately, a compressed air audit presents an opportunity to pinpoint areas for cost savings and establish a more efficient operational framework.

Reduce Compressed Air Costs by 25-50% With an Air Audit

When trying to lower operating expenses, many companies overlook the potential savings achievable through effective management of their compressed air systems. Experts suggest that a substantial majority of users could cut their costs by 25-50%.

Pneumatic Systems’ professional compressed air audit is designed to unlock these significant cost reductions by measuring current flow rates, energy usage, and operating pressure. These audits provide crucial data to identify areas of improvement in your air system. Numerous plants are currently operating with 50% more compressed air horsepower than required for their operations. An air audit not only leads to gradual operating cost reductions but also has a positive environmental impact.

Did You Know...

Utility companies frequently extend rebates that can cover the entire cost of energy studies. In some cases, they provide funding for energy-saving projects, contributing up to 50% of the total project cost or provide incentives such as 12 cents for every kilowatt saved over the course of a year.

Get a Professional Air Audit From Pneumatic Systems

Many manufacturing facilities overspend on the operation and maintenance of their compressed air system. A lot of these companies also suffer with poor quality compressed air. This is due to many poor practices both past and present. These include: inefficient equipment choices, poor system design and layout, inadequate maintenance practices, inefficient compressor controls, lack of useful storage and more.

Our technicians are trained to carry out a comprehensive compressed air audit, utilizing data to propose cost-saving solutions.

Why Invest in a Compressed Air Audit

- 25-50% Cost Savings

- Reduce the risk of equipment failure

- Reduce energy and repair costs

- Reduce energy consumption

- Increase productivity

- Reduce unplanned downtime

- Improve the quality of compressed air

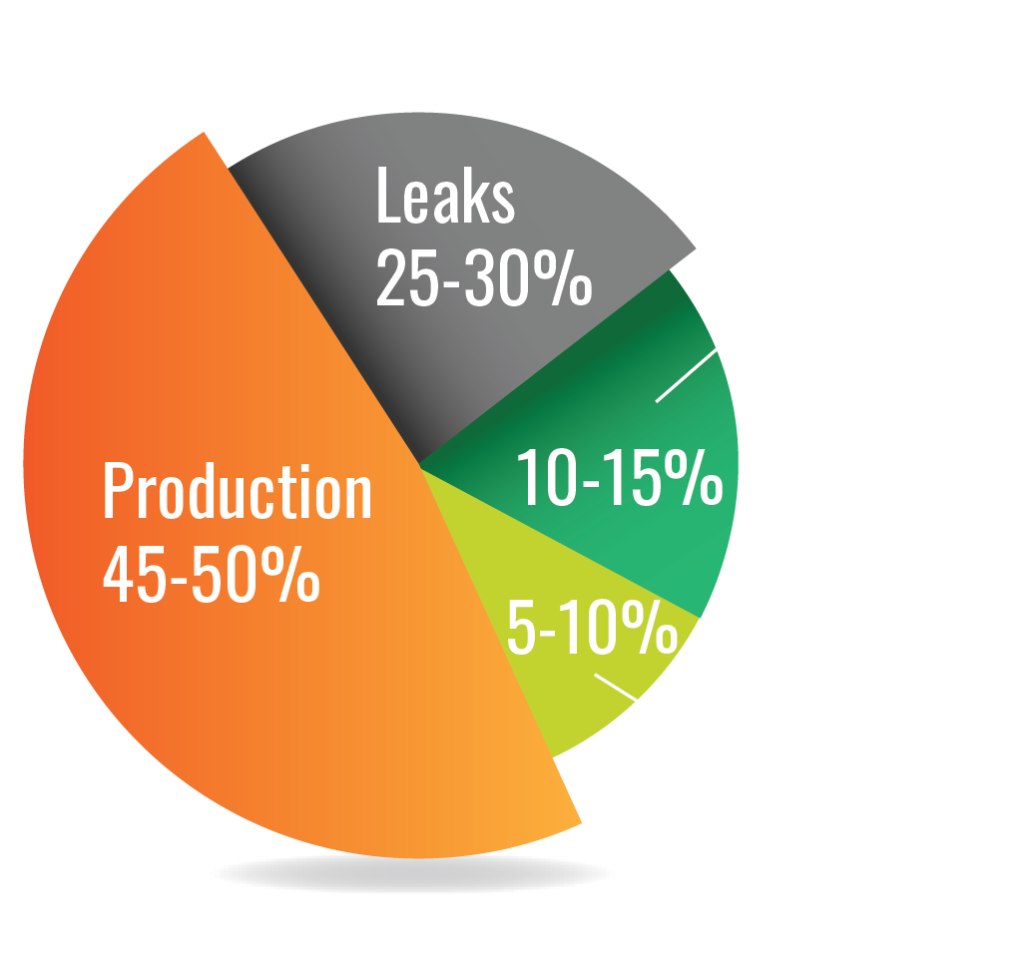

Leading Causes of Wasted Compressed Air